How Process Mining contributes to a robust supply chain

In all sectors, companies are dealing with an increased frequency and magnitude of disruptions. Businesses must quickly scale down and then ramp up their operations once demand returns. They have to switch product portfolios depending on the availability of components. Some of the events that have caused havock in the past decade include the Fukushima earthquake and tsunami in Japan, Suez Canal blockage, lockdowns related to Covid19 and variants, semiconductor shortages(link resides outside Axisto), staff shortages, war in Ukraine, exploding energy costs(link resides outside Axisto), high inflation.

Understandably, most of these disruptions took leadership teams by surprise. The worst of these disruptions have taken a toll on business output, revenue and profitability. Recovery can take months or even years.

Process mining provides the much-needed overview of the end-to-end supply chain and provides better insight and information for better, proactive collaboration internally and in the overall supply chain. Process mining also provides proposals for decisions with their consequences for real-time optimisation of flows.

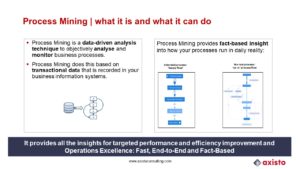

PROCESS MINING – WHAT IT IS AND WHAT IT CAN DO

It provides all insights for targeted performance & efficiency improvements: fast, end-to-end and fact-based.

DISCOVER AND IMPROVE YOUR REAL PROCESSES

APPLICATIONS OF PROCESS MINING

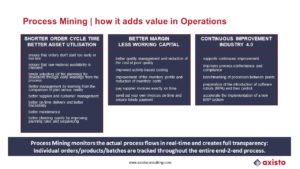

FULL TRANSPARENCY

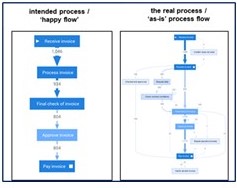

Instead of working with the designed process flow or the process flow that is depicted in the ERP system, process mining monitors the actual process at whatever granularity you want: end-2-end process, procure-2-pay, manufacturing, inventory management, accounts payable, for a specific type of product, supplier, customer, individual order, individual SKU. Process mining monitors compliance, conformance, cooperation between departments or between client, own departments and suppliers, etc.

Instead of working with the designed process flow or the process flow that is depicted in the ERP system, process mining monitors the actual process at whatever granularity you want: end-2-end process, procure-2-pay, manufacturing, inventory management, accounts payable, for a specific type of product, supplier, customer, individual order, individual SKU. Process mining monitors compliance, conformance, cooperation between departments or between client, own departments and suppliers, etc.

OVERVIEW OF THE ENTIRE SUPPLY CHAIN

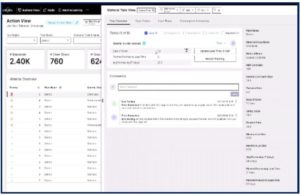

Dashboards are created to suit your requirements. These are flexible and can be easily altered whenever your needs change and/or bottlenecks shift. They create real-time insights into the process flow. At any time, you know, how much revenue is at stake because of inventory issues, what root-causes are and which decisions you can take and what their effects and trade-offs will be.

If supplier reliability is not at the target level at the highest reporting level, you can easily drill down in real-time to a specific supplier and a particular SKU to discover what is causing the problem in real-time. Suppliers could also be held to the best-practice service level of competitive suppliers.

MAKING INFORMED DECISIONS AND TAKING THE RIGHT ACTIONS

The interactive reports highlight gaps between actual and target values and give details of the discrepancies, figure A. By clicking on one of the highlighted issues, you can assign an appropriate action to a specific person, figure B. Or it can even be done automatically when a discrepancy is detected.

And direct communication with respect to the action is facilitated in real-time, figure C.

WRAP UP

Process mining is an effective tool to optimise the end-2-end supply chain flows in terms of margin, working capital, inventory level and profile, cash, order cycle times, supplier reliability, customer service levels, sustainability, risk, predictability, etc. Because process mining monitors the actual process flows in real-time, it creates full transparency and therefore adds significant value to the classic BI-suites. Process mining can be integrated with existing BI-applications and can enhance reporting and decision-making.