Challenge

Gone are the days when imported manufacturing goods were of a sufficiently inferior quality to challenge established market leaders. Technology and the free flow of capital have ensured that modern global competition in all sectors has the ability to compete internationally on price as well as on quality and service. This was the predicament our new client found itself in.

Things needed to change fast as the business was rapidly becoming uncompetitive and starting to lose market share.

Approach

The manufacturing process ran across two sites in two cdifferent countries under separate management structures. Together with a client team, we analysed the cost structure of the two businesses. We viewed the situation from four aspects:

- Vision and its deployment: in this client’s case, there had been a lack of joint vision and a lack of agreement on what the correct way forward was. This had led to dysfunction at the highest levels of the two respective sites and, as a result, this had trickled down into attitudes and behaviours.

- Systems and processes: if you have no alignment of purpose, then the very systems and processes that govern a business start to evolve separately and, in the end, they succeed in changing the priorities of the business in their day-to-day functions.

- Attitudes and behaviours: a lack of unifying vision and strategy, coupled with divergent systems and priorities, will eventually lead to non-aligned attitudes and behaviours, which cause operational performance issues at a group level.

- Organisational energy: when things start to go wrong, management generally tries to correct things by applying more pressure to comply with the established procedures. After a while, this starts to look like bullying and causes the employee to become stubborn and more dysfunctional. Behaviours spiral downwards as a result. Intervention is vital.

The project team analysed the performance of the business processes for sales and marketing, development, production, logistics and all support functions.

The breakdown in the relationship between the two sites meant that it was increasingly difficult for the directors to set strategy and agree joint objectives. The two sites were unwilling to cooperate and wanted to “do their own

thing”. This was a big problem as the only way to reduce the cost and increase efficiency across the whole business

was to cooperate fully “as one”.

We held a number of workshops within the organisation to gain insight into areas that needed improving. As a result of these workshops, we were able to develop new specific and measurable targets that would help resolve some of the issues between the sites.

During the final week of the initial “understand and engage” phase, we worked with the managers from both sites to develop a joint implementation plan. The objectives agreed lay at the extreme of what the organisation was capable of at that moment.

In other words, they were ambitious but achievable.

- Cost savings of €4.3 million – primarily through increased productivity in manufacturing and maintenance, but also in the support processes.

- A breakthrough in product quality, with the share held by top-quality items rising from 20% to 80%.

- Integration of two organisations to create one entity.

- Increase in on-time deliveries from 65% to 85% (based on first confirmed delivery date).

- Improvement of the innovation-to-market process: more focus, in line with customer needs, and a reduction in development throughput time.

Due to the size and nature of the changes required within the business, the implementation phase took 8 months. We had full-time “task-forces” on the client side, supported by Axisto. We all worked across the length and breadth of the organisation, from shop floor to executive level, on and across all shifts, day and night, twenty-four/seven. There was an incredible amount of energy and focus throughout the process.

The project team co-created a new Performance Management Framework. This ensured that the

following objectives were achieved:

- Transparency for everyone concerning current versus target performance levels.

- Decision-making process based on facts rather than intuition and “gut feel”.

- Relevant actions not just being agreed upon but actually being done and delivering the intended

results.

With this level of commitment and involvement, it was almost impossible for things to remain as they were. We found that the cross-functional nature of the teams and the breadth of implementation, supported by a common will to survive, led to a

transformation of attitudes between the two sites. As the project progressed, we saw collaboration starting to flourish where antagonism had once been commonplace. We found that cooperation in the face of a common adversary, with the right

support structures, generated an enormous amount of positive energy within the business – which at times was almost tangible in its nature.

Results

- An all-embracing integrated organisational structure that matched the company’s strategy.

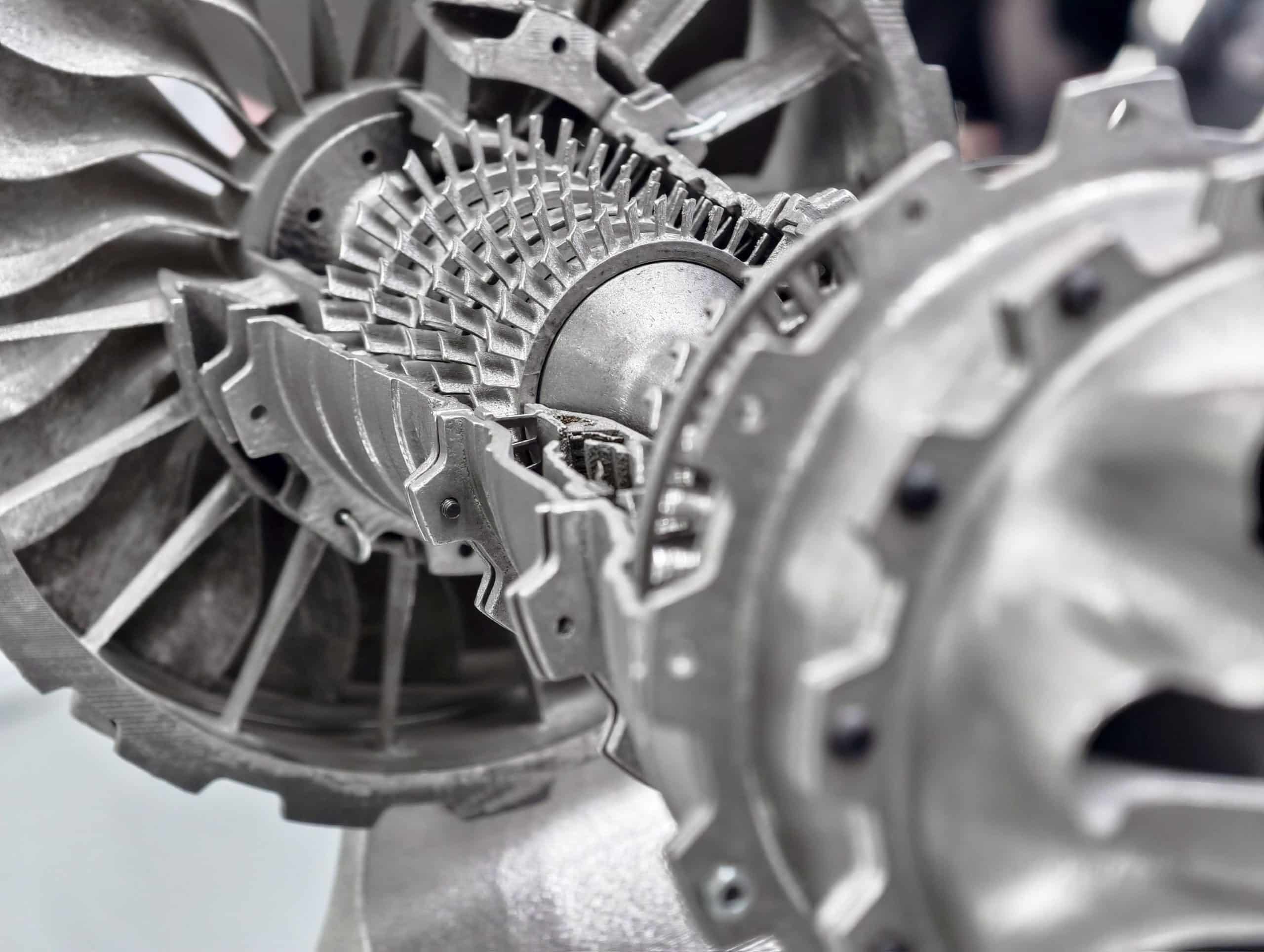

- A quality breakthrough by which the share of top-quality metal components increased from 20% to 90%.

- Improved productivity, both in manufacturing and in the development and support departments, resulting in cost savings of €4.3 million.

- On time delivery performance exceeding 85%.

- Improved time to market achieved by focussing on the right projects and by good resource planning and project management.

“I was amazed how quickly an abrasive relationship between the two sides of my

organisation changed into a productive, intensely cooperative relationship, right

down to the personal level.” – Business Unit Manager

During subsequent site visits we witnessed the 100% integration between the sites at all levels. They are capitalising on the new performance management framework. This is helping them to drive the productivity and reliability improvements even further.